The Fact About gearbox cvt That No One Is Suggesting

The Fact About gearbox cvt That No One Is Suggesting

Blog Article

When the power output is simply too small, the generator is disconnected, as well as Electricity is saved within the flywheel. It's only in the event the velocity on the flywheel is ample which the kinetic energy is converted into electric power, intermittently, at the pace essential through the generator.

For every revolution with the little gear, the bigger gear only turns a fraction. It’s like employing a reduced gear in your pushbike. And whenever you drive a car in initially (cheapest) equipment, you’ll know you can rev the engine quite substantial along with the car or truck doesn’t go quite speedy – this gearing is the reason.

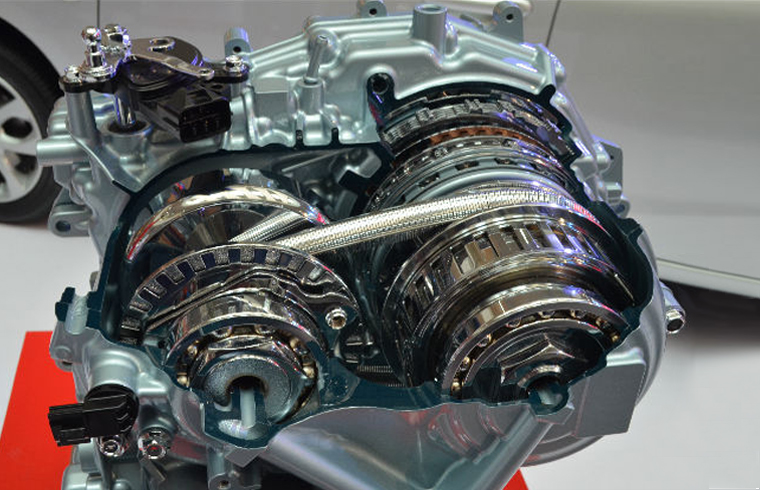

when the motor vehicle needs pace ratios, the feeding conical pulley (sheave) more than the enter shaft moves to the fastened pulley which in turn shifts the Component of v-formed belt wrapped around the enter pulleys towards the higher cross-sectional A part of the conical input pulleys.

Should you be shopping for a whole new commuter automobile or crossover, you might have identified that the model you prefer includes a continually variable transmission (CVT).

It had been these kinds of a superb time for Nissan. At that time Nissan was one of many very first pioneers in equipping CTVs in automobiles. And Talking frankly, we will’t deny the benefits of CVT transmissions simply because utilizing CVTs can improve substantially the gas efficiency of the vehicle. And Below are a few on the remarkable functions of Nissan CVT transmissions:

A continuously variable transmission (CVT) is really a transmission that operates on an ingenious pulley method that instantly differs the transmission ratio, making it possible for an infinite variability involving optimum and cheapest gears without discrete methods or shifts.

The most obvious application to get a CVT is once you’re striving to guarantee most gasoline performance, hence why Subaru has paired Boxer engines and all-wheel push (all-wheel push provides fat and might have an affect on gas consumption driving up the relative fuel consumption of the Subaru compared by using a non-AWD SUV in the same phase) by using a CVT.

November 16, 2024 Eric Williams When deciding in between eCVT and CVT transmissions for your automobile, you’re probably taking into consideration efficiency and functionality. eCVT delivers an infinite range of gear ratios, improving upon fuel financial system and driving working experience.

A CVT delivers almost all of the identical simplicity of use that classic automatics do. 1 selects Dive or Reverse, as well as CVT then handles the engine’s speed range options.

What What this means is for the driver is that the motor can go directly to the ideal rev range for the given circumstance. This rev vary is typically both the one that provides the most effectiveness, most electric power, or most torque. carian seterusnya As soon as in its content rev vary, the engine just retains its revs and also the gears “transform” because the relative dimensions of the two pulleys transform.

CVTs are many of the smoothest gearboxes, much too. Without having Actual physical gears to swap between, there’s no jolt or pause mainly because it modifications up throughout the gears like some common automatics. Acceleration is constant and linear, and could make the driving practical experience much more at ease.

Their improvement coincided While using the rise of hybrid technological know-how, giving an innovation more than common CVTs by combining electric motors and Highly developed Handle systems. Manufacturers like Toyota have been pioneers In this particular field, incorporating eCVTs in types similar to the Prius to enhance The combination of hybrid technology with transmission effectiveness.

With all in their advantages, CVTs do have some shortcomings. In America, they are still making an attempt to beat a picture difficulty. The Subaru Justy, one example is, was known as a gutless micro-vehicle. Typically, belt-generate CVTs had been restricted in the quantity of torque they could manage and had been greater and heavier than their automatic and manual counterparts.

The design basic principle dates back again to before the 1930s, with the first design and style intended to change rotary motion to oscillating movement and back again to rotary movement employing roller clutches.[18] This style and design stays in production as of 2017, to be used with reduced-velocity electrical motors.